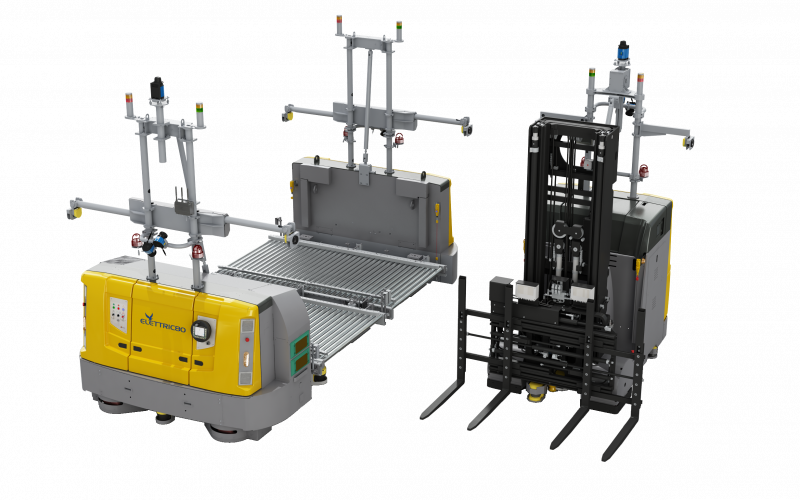

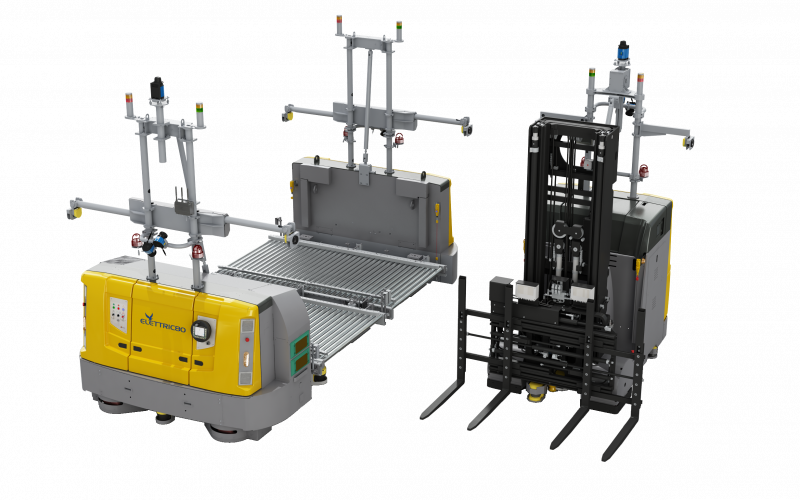

Automatic and laser-guided vehicles (AGV & LGV) designed to ensure the highest level of efficiency and safety in a 4.0 factory.

Automatic and laser-guided vehicles (AGV & LGV) designed to ensure the highest level of efficiency and safety in a 4.0 factory.

Automatic Guided Vehicles (AGVs) and Laser Guided Vehicles (LGVs) are reliable, fast, and flexible systems that provide the highest level of efficiency and safety, reducing time, cost, and margin of error within any automated industrial system.

Our AGV/LGV systems’ portfolio is various, and each solution guarantees the automation and optimization of all plant flows - reducing time, cost, and margin of error.

From the entry of raw materials to the warehouse and shipments' total management, they can move autonomously, streamline, and improve the intralogistics operations within a production system or a distribution center.

Our AGV/LGV systems guarantee, for all solutions:

SM.I.LE80 manages AGVs and LGVs' activity inside the factory. The software platform coordinates the intralogistics flows and movements of the AGVs/LGVs fleet, manual and robotic activities, allows dialogue with the customer's ERP and guarantees the whole system's real-time remote supervision.

Thanks to 3D Mapping technology, it is also possible to optimize trajectories within new (greenfield) or existing (brownfield) plants.

Our AGVs/LGVs can detect at 360° the presence of obstacles and people within the environment they operate, making the work area safe thanks to the Proximity Laser Scanner (PLS) devices.

The latest generation of lithium batteries with Flash Battery ® technology allow to maximize the systems’ efficiency by reducing recharge times and wear and tear of the machines.

We design AGV/LGV systems that boost different production sectors: mainly tissue, beverage, and food, as well as ceramic, plastic, wood, personal, and home care.