Designed to offer a custom response to customer needs, they ensure production line reliability and speed.

Designed to offer a custom response to customer needs, they ensure production line reliability and speed.

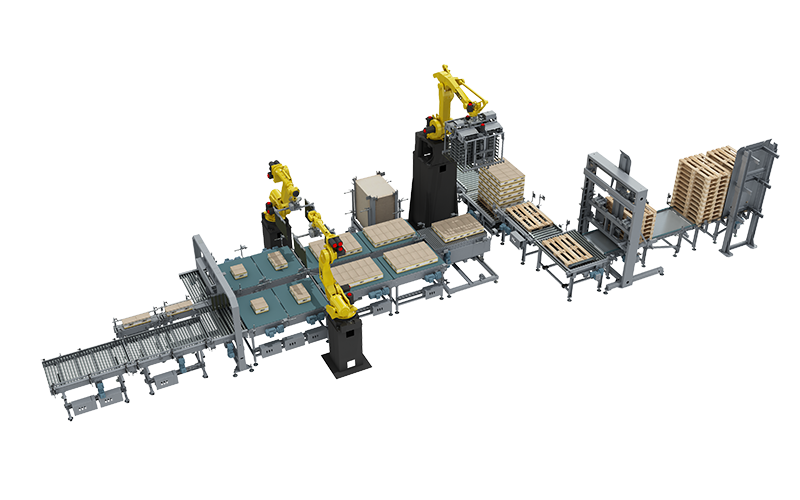

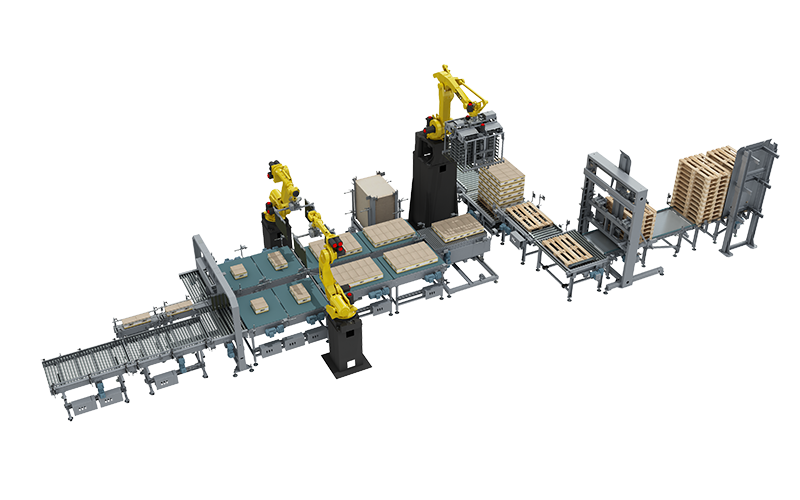

All our palletizing solutions dialogue with robotic wrapping and labeling systems, automated laser-guided vehicles; thanks to the SM.I.LE80 software platform, they ensure fully automated and integrated end-of-line management. They are directly connected to production lines and operate at speed with maximum reliability.

Palletizers automatically stack finished products, in cardboard boxes or trays, onto pallets, managing diverse product types quickly, flexibly and with extreme delicacy. The robot handling pickers are indeed designed to reduce pressure on the finished goods, thus preserving their integrity.

All solutions are designed based on customer requirements and meet the needs of tissue, beverage and food companies in a timely manner.

Different models are available to best suit your production site, the type of equipment installed therein and the speed of your line or lines.

Our robot handling pickers are designed to reduce pressure on the products, thus preserving their integrity.

All automatic palletizers are managed by state-of-the-art, intuitive Human-Machine Interfaces for simple, efficient operation, ensuring maximum speed and flexibility across the entire system.

Our robotic palletizers are designed to interface with AGV and LGV automatic guided vehicles and guarantee constant data monitoring. State-of-the-art Auto-Pallet Patterns software makes it quick and easy to introduce new product formats.

E80 Group also produces palletizing islands without the use of pallets in the production area. Insertion takes place during storage and this solution offers numerous advantages, in particular: it prevents product contamination, especially in the food sector; it increases system flexibility, leaving the choice of pallet type free, to be inserted just before warehousing; it reduces the footprint of the island.