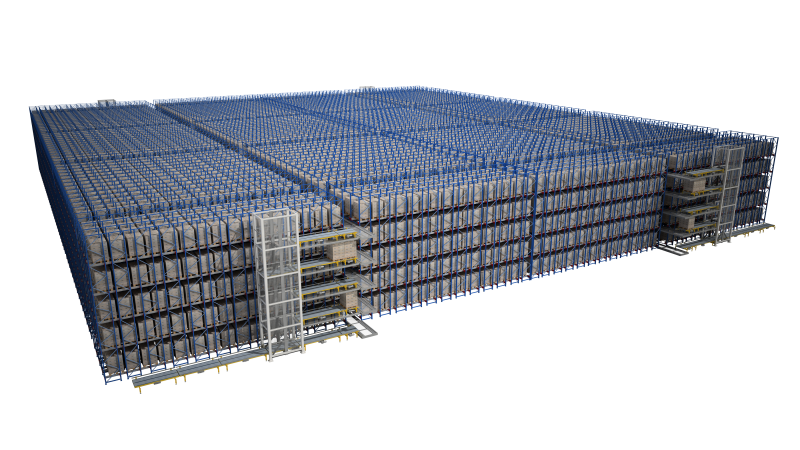

Multi-depth storage and independent handling on all levels

The SMART STORE high-density automated warehouse provides multi-depth pallet storage with independent movement at each level. It can be implemented in brownfield and greenfield projects. The combined use of shuttles and satellites offers, in safety, high performance and top-notch reliability. The system is provided with battery-powered shuttles on all levels that carry a satellite, that is also battery-powered, and recharge it at the same time. The satellite collects and transports the pallets to the storage channels while the shuttle transfers the pallets to the inlet and outlet headers of the warehouse. By using elevators connecting the various levels, the pallets are transferred to and from the inlet and outlet bays of the warehouse.

Advantages:

Optimization

- Maximum storage density for large production and distribution volumes.

- High operational cadences.

- Reliability.

- Accessibility.

- System modularity.

Integration

- The SM.I.LE80 software platform governs the storage systems, input/output peripheral units and LGVs/AGVs.

Flexibility

- To provide personalized answers to the customer’s needs.

- Studied and customized according to the operating parameters of the factory and using discrete-event simulation software, customers can compare different scenarios of the same system to verify all functions and select the best-operating logics for absolutely reliable results.

Energy efficiency

- Low maintenance costs and energy savings by exploiting the regenerative features on the lithium-ion batteries powering the satellites and the shuttles.

- Automatically and daily monitoring of all the batteries installed daily by the Flash Data Center software developed by Kaitek Flash Battery for Elettric80.

Safety

- Provided with safety systems for independent access to the various levels.

- Can be equipped with fire protection, lighting and air conditioning systems.

More than 450 integrated solutions

More than 2800 robotic systems

More than 9000 AGVs and LGVs

Since 2016, 50 automated high-density warehouses

Italian

Italian