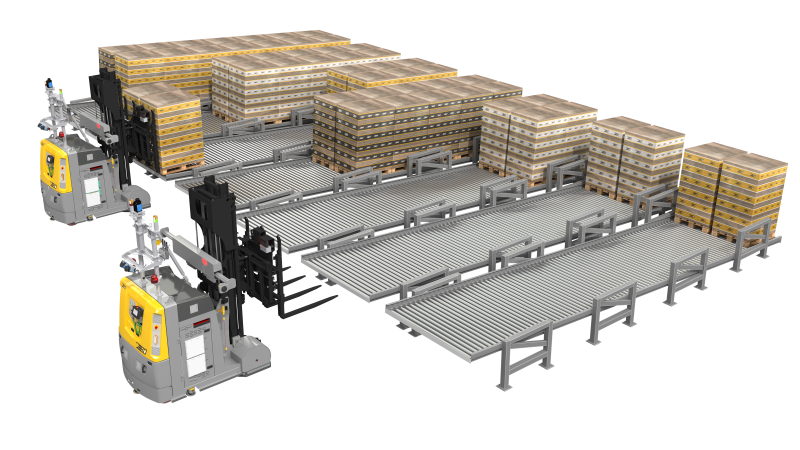

Multi-level sloping racks exploiting gravity for pallet transport. This solution is ideal for lines from 4 to 40 meters deep.

The pallets are deposited on a dynamic line with braking rollers, equipped with electromagnetic or mechanical devices, to control and adjust the speed so that it is always constant.

This system's cost, higher than others, is amply compensated by the high density of storage and the possibility of using a FIFO (first-in, first-out) management that allows you to deposit the pallet always in the last place and take the necessary goods from the first, thus optimizing the movements within the warehouse.

The Gravity Rack system requires great precision in taking back goods and technologically advanced pallet recognition and identification systems to recognize pallets that are different from each other even if positioned randomly.

Advantages:

High storage density

- With a reduced need for automation, this system provides high storage density and high throughput.

- Excellent compromise between sustainability and efficiency

Reliability

- Solid mechanics to have the last pallet always separated from the others

- The system is perfectly integrated with AGVs/LGVs, which allow for easy handling of goods, thanks to the vision system on the trolley (with LMS laser scanner) so that the forks can independently pick up two pallets.

Optimized truck loading flow

- During truck loading operations - which can be carried out in mixed or automatic mode with AGV/LGV systems - the minimum distance between the picking and loading point is guaranteed.

More than 450 integrated solutions

More than 2800 robotic systems

More than 9000 AGVs and LGVs

Since 2016, 50 automated high-density warehouses

Italian

Italian